60 meter long rotor blades on colossal towers are not only a very impressive sight, they also involve a problem that has not been discussed much so far: erosion of the rotor blade surfaces. Every grain of sand and every drop of rain containing contaminants may impact the material of the blade and reduce the efficiency of the wind turbine. In addition to the size of the turbine, its location also plays an important role. Erosion is greatest in offshore and desert areas.

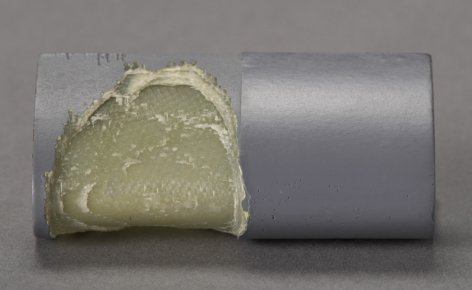

It is, of course, possible to repair erosion damage. This, however, entails comparatively high costs, which significantly worsen the economic efficiency of the turbines. With its 3M Wind Blade Protective Coating W4600, 3M has now developed a coating that protects the surfaces of rotor blades two to three times longer than previous coatings. With this coating, the revenue of a wind turbine can be increased by up to 100,000 euros per year. A single coating for an entire rotor costs less than 1,000 euros. "Prevention is thus much more cost-effective than subsequent repair," said Christian Claus of 3M's Renewable Energy Division in Neuss.

According to estimates of the "Bundesverband WindEnergie e.V." [German National Wind Energy Association], there were nearly 22,000 wind turbines in Germany in mid 2011. Coupling this figure with the results of the study leads to potential savings of more than 2 billion euros per year.

The study "Effects of Leading Edge Erosion and Erosion Mitigation Strategies on Wind Turbine Blade Performance" can be provided on request.