The software is also unique in that it ships with an “Optimizer”, which identifies downsizing potential and thus guarantees the highest possible energy efficiency and power density throughout the drive train.

Any number of axes configured in one project

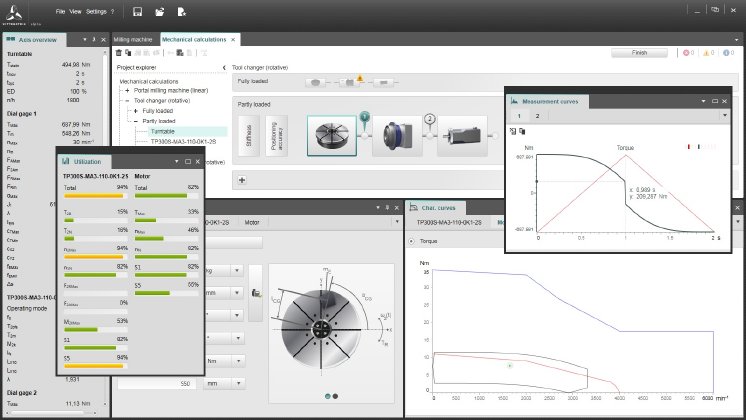

Motion profile, load case, mechanics – users can choose between several possible entry levels when they embark on a design project. The software enables precise simulations of motions and loads because all a drive’s most common basic applications as well as the most frequent movement kinematics and machine mechanisms can be selected directly. A crank, telescope and centre winder are now integrated over and above the applications already implemented in cymex® 3. Other variants can be configured in a modular way. cymex® 5 allows any number of axes to be defined at once. It also now permits several axes and variants to be analyzed and evaluated simultaneously in a single project – a time saving for designers of up to 60%. What’s more, each user can customize their own GUI layout with cymex® to create a personal look & feel.

End-to-end sizing and design with full documentation

To support the design of the drive train, cymex® 5 has access to a regularly updated database listing around 14,000 motor versions from more than 50 different manufacturers plus more than 8000 WITTENSTEIN alpha gearheads and 200 combinations of WITTENSTEIN linear systems. After comparing the geometry, the software derives bespoke drive configurations and automatically suggests suitable attached components. At the end of the sizing process, the user can generate the full calculation documentation directly, create data sheets for the gearhead and motor and display 2D or 3D CAD component data.

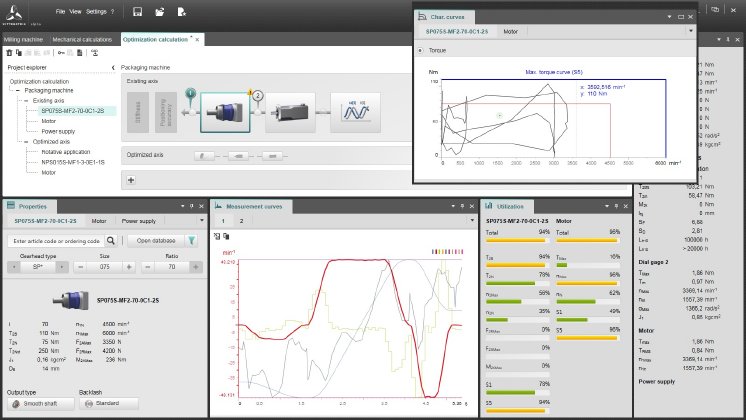

“Optimizer” improves energy efficiency and power density in the drive train

cymex® 5 is shipped with an optional “Optimizer” that is the only one of its kind to date for sizing software. This tool identifies downsizing potential – especially in machines, axes and powertrains that have already been configured. A machine’s existing controller parameters, such as the current or voltage profile, can be read out for this purpose and imported into cymex® 5 in order to optimize the train’s energy efficiency. Furthermore, the Optimizer knows, for example, whether a smaller sized motor / gearhead unit could be used instead without compromising performance. Undersized drives can be adapted with the help of the Optimizer’s recommendations.

Drive design without language barriers

cymex® 5 can be used in any of eleven European and Asian languages. The calculation documentation and product data sheets, too, reflect this impressive linguistic diversity.

User friendliness, versatility, internationality, downsizing – efficiency engineering with cymex® 5.