Manual visual inspections are simply unable to compete with the latest machine vision technology from either a qualitative or a cost perspective. However, photovoltaic manufacturers can only hold their ground on the market by offering high-quality, clearly classified products. Optical quality inspection during photovoltaic production are therefore critical to sustainable success in this highly competitive market.

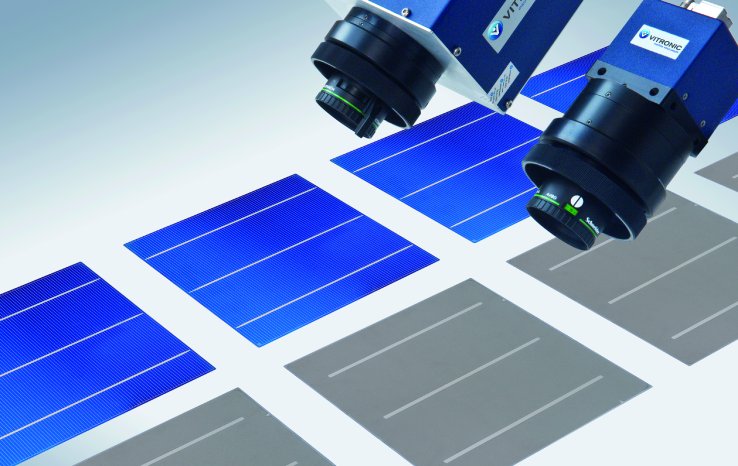

Benchmark tests have proven the technical performance, reliability, and reproducibility of the automated inspections offered by various European and Asian suppliers. The results are self-explanatory - VINSPECsolar inspection systems are ahead of competitors. The VITRONIC solutions impressed our customers by offering maximum detection reliability with a clearly increased yield.

Even before the turn of the year, the impressive performance led to an upturn in the sales figures in this area. In the first half of this year, several dozen systems have been purchased to equip new solar cell production lines as well as to retrofit existing lines. These inspection systems are not only used to classify the finished solar cells but are also seamlessly integrated for several inspection tasks – following the cell texturing, coating, and metallization/printing stages.

High resolution print inspection

The latest generation of VINSPECsolar camera systems is delivering impressive results. The very high pixel resolution of 20 µm, the robust sensor unit, the throughput of up to 4,000 wph (wafers per hour) and well adapted and differentiated classification options master the inspection and classification tasks required for latest high-efficiency cells and modern metallization with very thin fingers and/or double print.

High reliability in cell testing

In cell testers and sorters, the high-performance defect detection combined with reliable and differentiated color classification ensures optimum results – for both small reflective substrates and highly reflective metal grid. With the aid of VITRONIC’s commissioning, calibration, and monitoring tools and procedures, the benefits of the line scan camera technology in these VINSPECsolar systems can be used efficiently and in a customer-friendly manner. Integrated in standard production equipment, the physical performance, robustness, and reliability ensures that the investment pays off within months. VINSPECsolar offers an outstanding achievement of best underkill and overkill false detection rate.

High performance of microcrack inspection

With the inspection systems of VITRONIC only perfect quality wafers will be processed. Especially micro cracks and breakage can be detected with the high performance of the VINSPECsolar inspection system. It differentiates between those cracks which are relevant for efficiency and cell survival from those that are not. The inspection system also measures granularity, the grain structure at multi crystalline wafers and detects severe saw marks, holes and chippings.

VITRONIC at trade fair EUPVSEC

The complete range of camera based VINSPECsolar inspection systems will be presented by VITRONIC at the European Photovoltaic Solar Energy Conference in Amsterdam from September 23 - 25, 2014 in Hall 1 Stand D15.