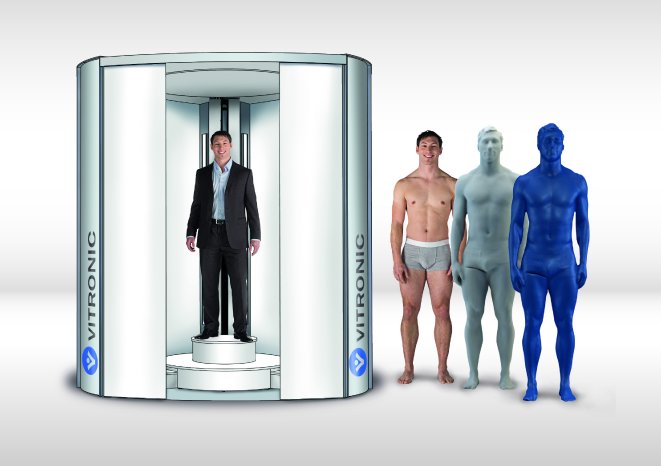

At the end of October this year, VITRONIC once again attended and exhibited at the annual international "3D Body Scanning Technologies" conference in Lugano. At the booth, the Wiesbaden-based company presented its innovative design for the latest generation of body scanners. An increased number of conference attendees and a particularly high level of interest in the VITUSbodyscan concept ensured a steady stream of visitors to the booth.

For the first time, the conference included a program of four presentations on various aspects of "3D Scanning to 3D Printing." The speakers reported on the latest developments in this market.

VITRONIC Sales Manager Julian Martini discussed the range of applications for the VITUSbodyscan and the newly developed "Scan2Print" function. In less than seven seconds, the new body scanner creates three-dimensional color scan files of people, objects, or animals in extra-sharp detail. The post-processing software used for this purpose features a “Scan2Print” function and closes any blind spots or "holes" on the surface. A high-resolution image with a seamless surface is ready after just a few minutes. With additional, individualized post-processing of the color textures, this image produces a print-ready template that can be used to print color miniatures of the highest possible quality.

The new 3D-whole body scanner will be launched in the first quarter of 2015.

For more information about the new VITUSbodyscan, please visit us at:

http://www.vitronic.de/...