The theme of the congress was “From Toxins to OMICS: Health, Safety and Well-Being.” Current and latest scientific innovations were discussed in 23 scientific sessions, comprising 9 symposia, 8 workshops, 1 oral session, 3 continuing educational courses, one round table discussion, 2 plenary lectures and 2 key-note lectures. During the congress over 800 posters were presented.

VITROCELL® SYSTEMS participated in the exhibition and presented its broad product program of equipment for the in vitro analysis of airborne substances such as gases, nano particles and complex mixtures.

Key interest was shown in the VITROCELL® technology for the direct exposure of lung epithelial cells to nano materials at the air/liquid interface. New turnkey systems using aerosol generation from liquids, solutions, suspensions and dry powder were presented.

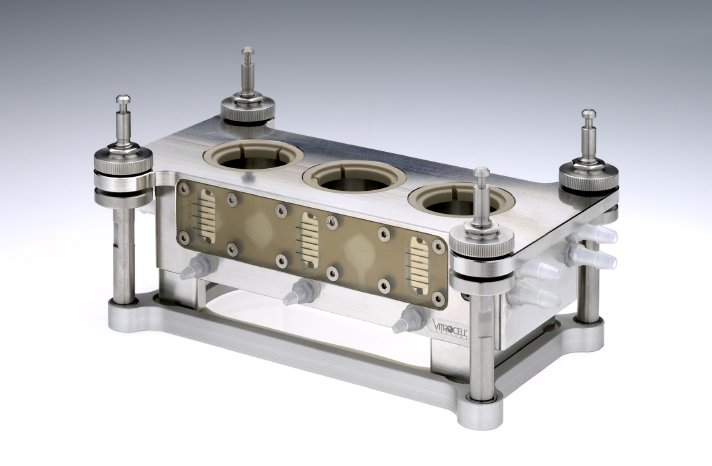

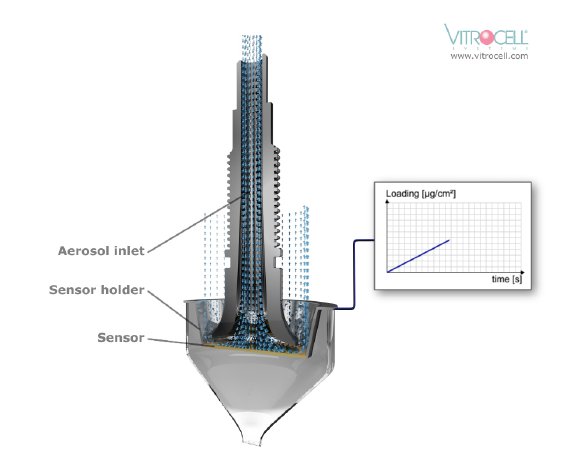

Special highlight was the introduction of the microbalance sensor which can be integrated in the VITROCELL® 6 PT stainless steel module. The deposited particle mass can now be monitored online by mass per area over time. This joint development with the Karlsruhe Institute of Technology was also theme of a poster presentation.

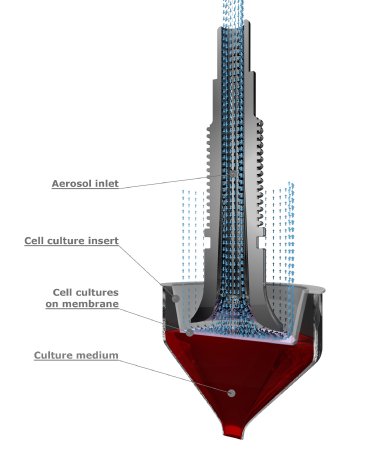

In using the VITROCELL® direct exposure modules, the cells are first cultivated on membrane inserts (e. g. ThinCerts® from Greiner, Costar® from Corning or Falcon® from Becton Dickenson). The membrane inserts are then placed in the VITROCELL® modules which are tempered at 37°C. The medium supply is performed either static or by permanent exchange so that the cells receive the cell culture medium from below through the membrane of the insert (air/liquid exposure). The special aerosol inlets of the module are from stainless steel with a PFA-based surface treatment and deliver the particles to the cells by a low vacuum flow. As the cells are not covered with medium, they are exposed in the most efficient way.

The customers of VITROCELL® SYSTEMS are leading medical and environmental research institutes as well as the pharmaceutical and other industries.

More information: www.vitrocell.com