The main points of the workshop are coordinated to product developers, application engineers, process managers and production planners looking for information about the perfect balance of material, machine and dosing process as well as trends of the manufacturing technology.

LED's are currently said to be the most economic and future oriented lighting systems in the market. Unquestionably the main characteristic feature is the enormously low energy consumption. In addition, they can be adapted on many applications with quick switch cycles intelligently and allow therefore a big range of implementation. The requirement of these light-emitting diodes is estimated till 2020 at a rate of about 70 percent in the worldwide lighting market (Source: „Lighting the Way“ by McKinsey). With increasing expansion of this technology, e. g. also in the lighting system and traffic technology of the public sector or automotive manufacturing, rise in parallel the demands for failure security, material permanence and quality of the production processes.

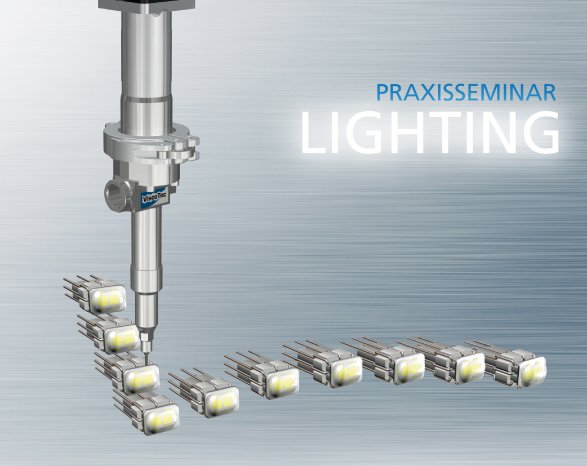

The practical seminar this year looks closely at the used adhesives and sealants for LED-based lighting systems. In cooperation with material manufacturers the necessary dosing processes are introduced for the bonding, sealing, isolating and potting within the LED production. Another point is the setting of tasks to form these processes economically optimally.

Presentations of external lecturers offer a general overview about used media (e. g. adhesives, sealants, potting materials), about surface pretreatment and the dosing process in LED manufacturing. The knowledge transfer is supported under realistic conditions by several practical stations which introduce 1K-and 2K-dosing tasks with most different materials.

Participants have the possibility to have a look together with our dosing experts at concrete settings of tasks and dosing projects - for highest process stability and cost control. Further information about the workshop on www.viscotec.de/praxisseminar