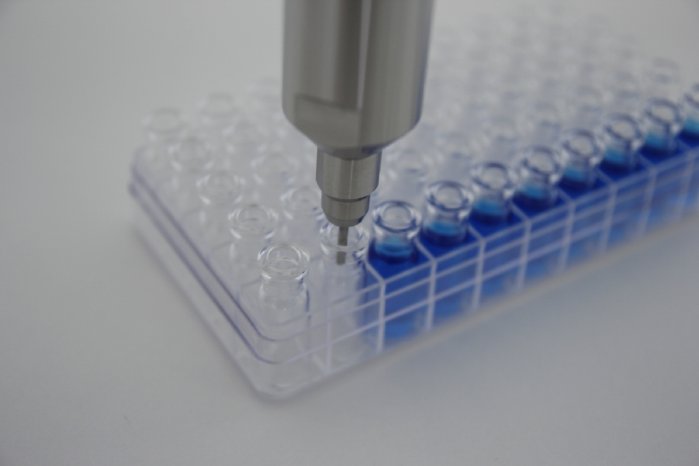

The task is realized with a Pharma Dispenser 3VPHD8 in hygienic design; the stator consists of the elastomer VisPharm-H FDA which is perfectly suitable for the pharmaceutical industry. The hygienic pharmaceutical pump has a dosing volume of 0.35 ml/turn and is driven by a corresponding hygienically sealed servomotor (incl. gear). To achieve a precise dosage the Pharma Dispenser is controlled by the pharmaceutical control - also hygienic design - which is assembled in a stainless steel cabinet with a graphical display (touch panel). To prevent dripping of the product at the end of dosing a freely selectable reverse-flow can be set.

- Reliable, accurate and reproducible filling of medium to high viscosity media

- Maximum preservation of high quality pharmaceutical products by low-shear and pulsation-free continuous delivery

- No dripping or stringing of the product (reverse-flow possible)

- In accordance with the guidelines: EHEDG, FDA, 3.1, GMP compliant design

- Easy to clean with its simple, tool-less disassembling and assembling - all wetted components are autoclavable

The pharmaceutical is conveyed continuously, high in precision, structure gentle and almost pulsation-free - especially suitable for abrasive, highly filled or shear sensitive media. The basis for this is being created by the endless piston principle technology of the Pharma Dispenser. A helical modeled stainless steel rotor is moving within a fixed stator and thus forms separated from each other closed product chambers. During operation of the hygienic pharmaceutical pump the chambers will be moved continuously to the outlet. Through modern production process it is ensured that the closed chambers in the rotor-stator-system always have the same size and volume. This volume is furthermore direct proportional to the numbers of turns of the rotor. Additional controls or checks of the volume – for example inductive flowmeters – will not necessary. During standstill of the Pharma Dispenser the product´s journey will be closed by the chambers inside the rotor-stator-system. In the most applications downstream valves are not necessary. After dosing the direction of the rotation of the drive can be reversed. The product will be sucked in shortly. The product string tears defined – very good dosing results are the outcome. In addition no pack surfaces or parts of the filling system will be polluted or contaminated.

ViscoTec pharmaceutical dispensers have excellent cleaning properties due to the tool-less and quick and easy disassembling. The interior is dead spaced optimized. All wetted contact parts can be sterilized in an autoclave. The Pharma Dispenser itself meets the highest hygienic and cleaning standards and owns an EHEDG certificate (European Hygienic Engineering and Design Group). Used elastomers are FDA-conform. The documentation will be finished with a 3.1 inspection certificate DIN EN 10204 for all metallic components. To protect the materials against harmful environmental influences and to protect the environment against unplanned product leakage the seal housing specially designed for the pharmaceutical sector is equipped with a locking chamber (quench). The VPHD series was specially developed for applications in the pharmaceutical, the biotechnological and cosmetic industries.

The advantage of pharmaceutical control is to control the flow rate and the desired dosing volume with a simple but accurate system. By direct input using the Touch Panel the parameters dosing volume and speed, calibration and suck-back at the end of dosing (to avoid dripping) reliably can be set and supervised. The accuracy of the dosage is more than 99%. Controlling via a higher-level control is possible at any time. The SPS transfers the parameter, for example via profibus to the pharmaceutical control.