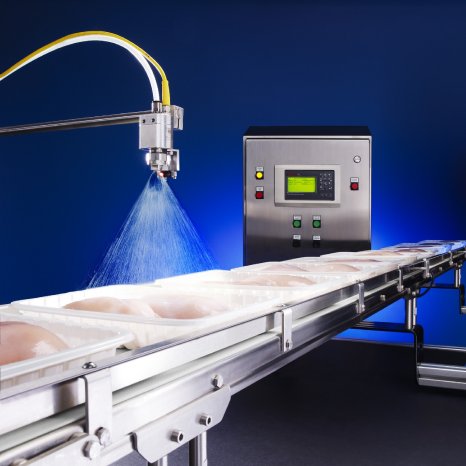

The Pulse Width Modulation Technology introduced by Spraying Systems supports the move to an always improved performance. The PulsaJet® automatic spray nozzle embodies this technology. While a hydraulic spray gun ordinarily delivers a fine spray pattern 100% of the opening time, this gun opens and closes up to 10,000 times per minute. For a given and constant pressure, the user only needs to adjust the Duty Cycle, i.e. the percentage of open versus closed time to control the throughput. This relies on electronics therefore it can be at least 1% precise and reproducible.

The PulsaJet® automatic spray nozzle applies mostly to low viscosity products: water, alcohol, thin oils and solutions of them. But, as the temperature reduces viscosity, this applies to a wider range of liquids, provided they are heated first: solid fat, sugar syrups, gels. Globally considered, a bakery is a burrow for spraying systems to find a place, but not for rest.

Think of it and here is the shopping list: spraying oil into funnels to allow dough transfer, pan lubrication, forming roll lubrication, humidity control in a proofing stove, bread scoring, surface wetting for adhesion of seeds, glazing with egg wash, moisture control after baking, flavoring with oil, depositing of a barrier film, gel application, chocolate enrobing, robotized decoration. More applications are found not in direct contact with the product but next to the process itself: mechanical chain lubrication, tank cleaning for example. Savings through efficiency range from 10 to 90%. Such an extent of applications requires a comprehensive knowledge of each and the experience in implementing them, a feat which Spraying Systems ensures worldwide.

Trade show participation: IBA

Hall A5 - Booth 375