Cyclists can use the corresponding VELODAPTIC app to create customized shifting programs. That means everyone always stays in the right gear, without having to shift manually. The app also accompanies cyclists on the road and records the GPS, movement, and performance data.

Top-class riding comfort

The FAG VELOMATIC determines the optimum shifting point according to the riding conditions depending on the cadence, force, wheel speed and uphill or downhill gradient and operates the gear hub or derailleur quickly, easily and precisely. The smooth gearshift operation is hardly noticed by the rider. He can conserve his energy reserves and is more relaxed when he reaches his destination or he can cover longer distances. In addition, reduced loads are placed on the chain and hub gear and premature wear is prevented.

The FAG VELOMATIC completely replaces manual shifting. The rider can change independently from "automatic mode" to "manual mode" using an optionally available and easy-to-use electric gearshift module in the form of a hold-to-run switch in order to shift gears manually for a sportier ride.

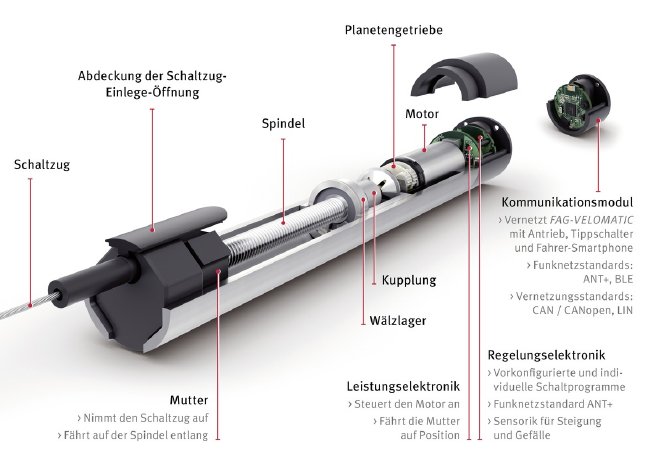

The communication module connects the FAG VELOMATIC with the electric drive system in an e-bike or the sensor bottom bracket in a conventional bicycle as well as the optionally available electric gearshift module and the rider's smartphone. The standard wireless sensor networks are ANT+ and BLE, interconnection standards are CAN, CANopen or LIN.

The perfect combination: FAG VELOMATIC and VELODAPTIC app

Cyclists can create individual shifting programs to suit their riding style in combination with the corresponding VELODAPTIC app. That means everyone always stays in the right gear, without having to shift manually.

The app works with both tablets and smartphones. The rider can choose between daytime and nighttime mode, depending on the light conditions.

The app records the following movement data: Speed, cadence, force, torque, uphill or downhill gradient, distance, position and a compass function. The cockpit always displays three sets of movement data, which the user can click through. GPS data for location determination and a map function are also available via the app. A statistical evaluation of kilometers traveled, meters climbed, calories burnt, forced used, cadence, torque and average and maximum speed is also possible. These data can be exported to other terminal devices.

Increased efficiency for an increased range

E-bikes require less electrical energy if the electric drive is operated at the optimum operating point. The FAG VELOMATIC comprises an electric linear drive with sensors. It is equipped with its own software and is able to communicate with any e-bike control systems. The optimum gear is selected in coordination with the rider and the electric drive. The e-bike drive therefore operates at the most efficient operating point, requires less energy, and the range of the battery is significantly increased compared with conventional, mechanical gearshift applications.

Space-saving and individually configurable

Thanks to its narrow, extremely light design (24 x 180 mm, weight approx. 200 g), the gearshift system can be fitted in the down tube or the seat tube and is not visible from the outside. This means the system does not spoil the visual appearance of the bicycle. The system is connected to the hub gear or derailleur via a short shifting cable.

The system's own controller and bluetooth interface offer a large number of possible combinations, for example, with a smartphone, additional sensors, control elements and drives.

Innovative motorcycle and bicycle components are a core area of Schaeffler's expertise as part of its "Mobility for tomorrow" strategy. The megatrends globalization, urbanization, digitalization, scarcity of resources, renewable energies and the growing requirements for affordable mobility are leading to changed, much more dynamic market requirements and business models. Schaeffler has developed its growth strategy to fulfill these changed market and customer requirements and utilize the enormous growth potential. In collaboration with customers and business partners, Schaeffler is actively shaping areas of focus, such as environmentally-friendly drives or urban and interurban mobility by carry out its own research and development and offers solutions for the mobility of tomorrow.