This year, the expert jury focused on the centrifugal pendulum-type absorber developed by the Schaeffler brand LuK, which is already used in different modern and efficient vehicles with internal combustion engines. The award was accepted by Dr. Wolfgang Reik, who is responsible for Advanced Development Automotive in the Schaeffler Group and Development at Schaeffler's LuK brand. "Schaeffler has successfully achieved a milestone in the history of vibration damping by integrating a centrifugal pendulum-type absorber in the dual mass flywheel (DMF). This innovation makes a significant contribution to improving comfort, fuel consumption and emissions", explains Dr. Reik. Downsizing and downspeeding are two approaches for reducing fuel consumption in internal combustion engines. There is a trend towards engines with a lower number of cylinders and developers are also focusing on reducing engine speed levels. This results in increased rotational irregularity of the crankshaft, which in turn necessitates new damping concepts. The centrifugal pendulum-type absorber is an innovative key technology for solving the vibration problems at low speeds. The award for the centrifugal pendulum-type absorber demonstrates the importance of Schaefflers's innovative detailed work and production expertise. It is also valuable confirmation of our innovative force, which is highly valued by customers."

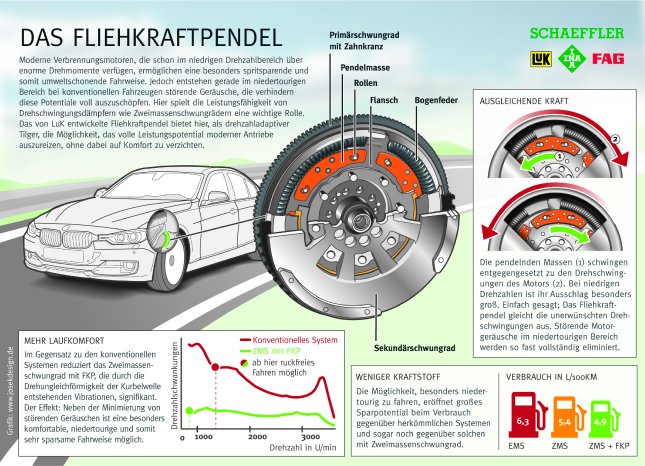

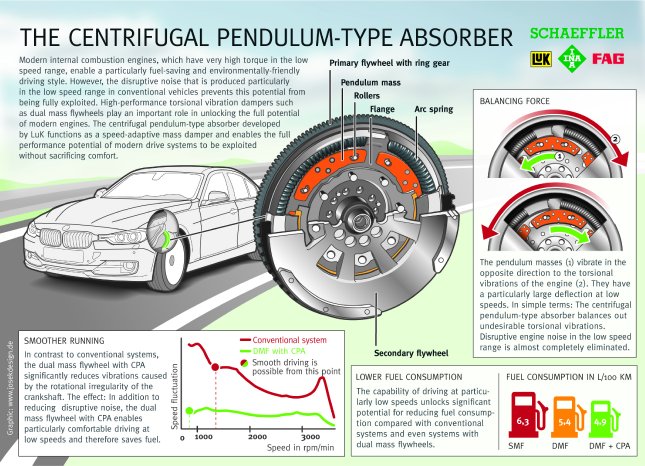

Using a centrifugal pendulum-type absorber means the conventional inner damper is no longer required in the DMF. The speed-adaptive damper without natural frequency is mounted on the flange of the DMF. The effective rigidity of the pendulum is generated by centrifugal force during operation. The selected order of excitation (for example, the firing frequency of the engine) can therefore be efficiently damped by making the relevant adjustments. Here, only relatively low pendulum masses are all that is required to reduce vibrations in the transmission by more than 70 percent. The DMF with spring mass system continues to provide basic insulation of the vibrations. In total, isolation degrees of up 90 percent can be achieved.

The dual mass flywheel with centrifugal pendulum-type absorber made its debut in 2008 with the launch of the BMW 320 d Efficient Dynamics Edition, which features unprecedented smoothness even when driving at low speeds. The LuK product range has now been extended by torque converters with centrifugal pendulum-type absorbers. This means this product innovation for minimizing vibrations in the drivetrain - as well as reducing engine speed and thus fuel consumption and emissions - has now found its way into vehicles with automatic transmissions controlled by a torque converter.

Schaeffler has now won the Steel Innovation Prize twice. In 2009, the lightweight balancer shaft with rolling bearing supports from Schaeffler's INA brand also won this renowned award.