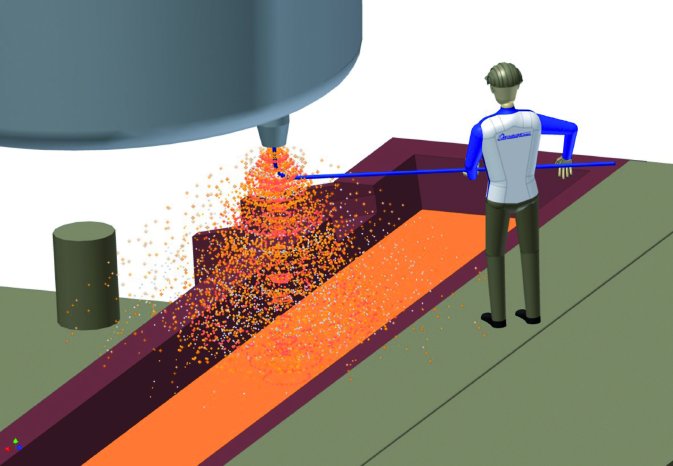

The slide gate opening systems by Reinguss are simple mechanical devices, which open casting channels in a short time. They redundantise the hazardous and time consuming oxygen lancing of the slide gate. This is how the systems increase work safety and save time by guaranteeing high steel quality at the same time.

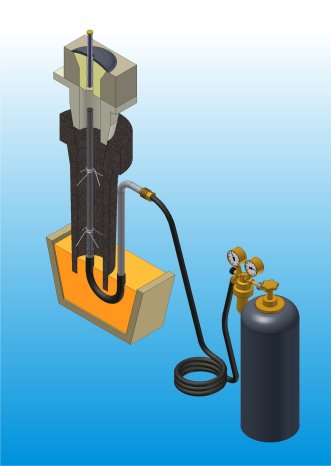

New is, that S.O.S.-P only works with gas pressure and does not contain a propelling charge. This is why any gas can be used, that is available on the casting platform, be it compressed air or CO2 with a pressure of up to 6 bar; nitrogen or argon with a pressure of up to 15 bar are also usable.

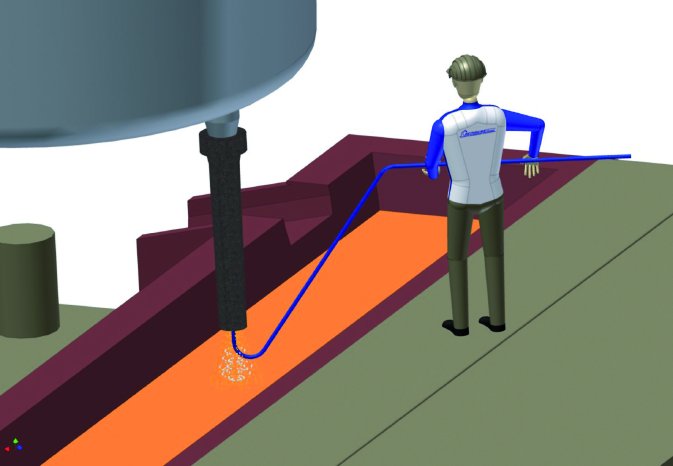

If the slide gate is clogged, the shroud tube is detached and the S.O.S.-P is inserted in the shroud tube. Flexible fastening claws are fixing it automatically in the right position. After the shroud tube is pressed on to the collector nozzle in casting position, the operator connects the power gas supply to the attachment of the adapter. The system is easy and safe to operate, since the hose connection is outside of the tundish.

After opening the gas supply, the gas pressure builds up inside the inner rod and catapults the cartridge located inside, upwards with a force of up to 350 N, when the predefined pressure is reached. It penetrates the clogging – the casting channel is open.

Since the shroud tube at this time is already in casting position, the liquid steel is not exposed to oxygen. The S.O.S-P with all its components is completely dissolved after start of casting in the liquid steel.

The price for the S.O.S-P is around 100 EURO due to the simple construction. This is why the expenses are marginal in comparison to time and quality loss or even an accident. The feasibility study of a professional operator has shown that savings of 300,000 Euro per year are possible when using the S.O.S system on solely 50 blocked ladles.