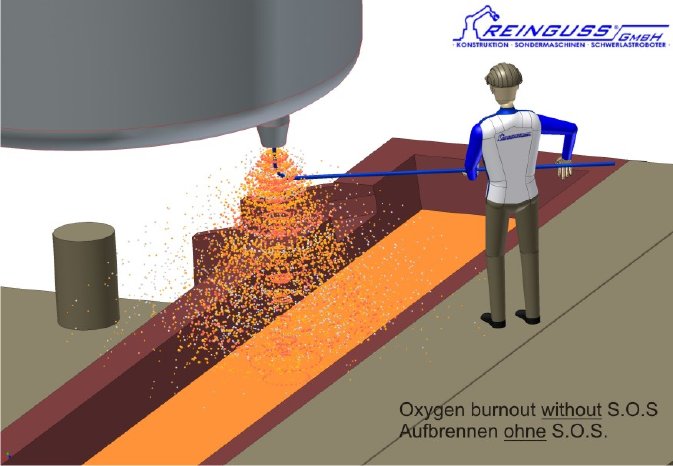

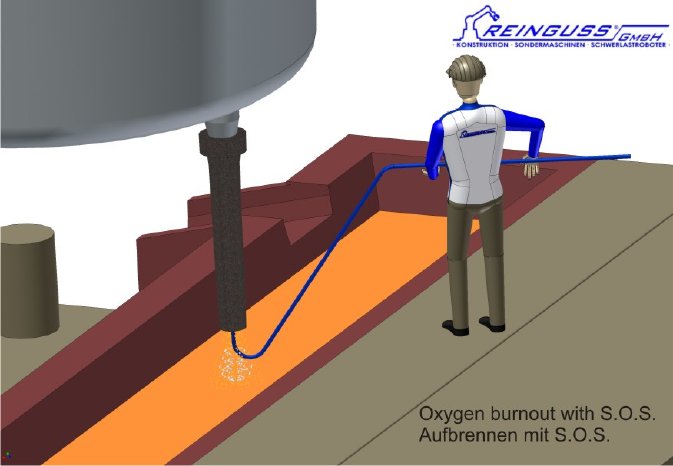

Slide-gate blockages are a common problem during continuous casting. The new slide-gate opening-system by Reinguss is a simple mechanical device, which burns out blocked casting channels within a short amount of time. It increases work safety and steel quality, since the burn out is performed after the shroud tube is pressed on the collector nozzle of the ladle. The S.O.S. can be used for open and submerged casting.

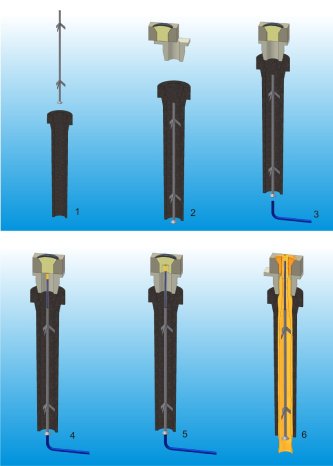

If the slide-gate is blocked, the shroud tube is removed from the nozzle and the S.O.S. is inserted inside the tilted shroud tube - according to the casting situation from top or bottom. Flexible tension springs keep it automatically in the right position. After the shroud tube is positioned back in casting position on the slide-gate nozzle, the operator connects the oxygen lance to the funnel on the lower end of the outer tube and opens the oxygen supply. The gas pressure drives the inner tube upwards including the enclosed starter unit. It ignites automatically and burns out the blockage with the support of the oxygen from the lance, until the melt is discharged.

Since the shroud tube is already in casting position at this time, the liquid steel is under no circumstances exposed to the atmospheric oxygen. After the start of the casting, the S.O.S. system resolves completely in the liquid steel with all its components.

For submerged opening, Reinguss supplies an adapter, which enables the oxygen burn out and connection to the oxygen lance outside of the tundish.

Due to the simple design, the price for the S.O.S. system is only slightly above 100 Euro. This is why the expenses are marginal in comparison to time and quality loss or even an accident. The feasibility study of a professional operator has shown that savings of 300.000 Euro per year are possible when using the S.O.S system on solely 50 blocked ladles.