Oil & Gas operations are heavily dependent on combustion based processes to supply the world’s growing energy needs. The PULSAR 4 is intended for monitoring the Refractory and Gas temperatures inside Sulfur Recovery Units, Sulfur Burner Furnaces, and Thermal Oxidizer Furnaces frequently found at these facilities.

“Any one of these vessels can force a shut down that will cost $1M or more per day”, said LumaSense CEO, Steve Abely. “Unplanned downtime eats into planned profits, whereas increasing uptime increases profit. The PULSAR 4 is a condition based maintenance system to protect refinery profits”, continued Abely.

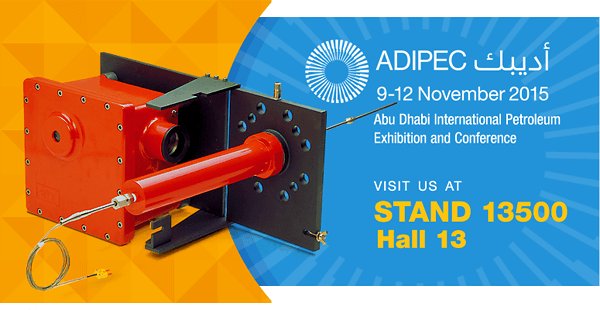

The PULSAR 4 is an explosion proof infrared thermometer (pyrometer) with the ability to see through flames and simultaneously deliver the Refractory Temperature and Gas Temperature with precision to 0.3° C and a range of 350° C to 2000° C. The PULSAR 4 Advanced features LumaSense’s propriety Smart Flame Measurement Algorithm (Smart FMA™) which accounts for flame transparency that can affect the temperature readings for a more precise view of activity inside these vessels. LumaSense’s updated and powerful InfraWin software interprets the data from the PULSAR 4 for analysis inside control room.

“Our Smart FMA™ technology, serviceability, and long standing relationships with major producers is what separates the PULSAR 4 from the rest”, said Gerard Ames, Managing Director of LumaSense Benelux, responsible for the E2T product range.

Customers with PULSAR II and III can leverage their existing infrastructure to upgrade these units to the new PULSAR 4 and its advanced capabilities.

The PULSAR 4 can be viewed during ADIPEC 2015, at booth 13500 in Hall 13, operated by LumaSense and the regional partner AIMS. Also based in Abu Dhabi, Analytical Instrumentation & Maintenance Systems (AIMS) is a leading supplier of analytical instrumentation and services in the Middle East and distribution partner for LumaSense products in the region.

About AIMS

Analytical Instrumentation & Maintenance Systems (AIMS) is specialized in providing expert service for analytical instrumentation, process solutions, SRU-optimization. Supported by experienced service personnel AIMS is considered as the fastest growing analytical company in the region. AIMS is the official distributor and service center of LumaSense Technologies BV.