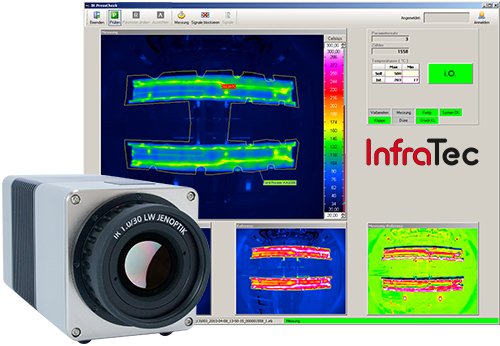

In the press-hardening process, metal parts are cooled so that the microstructures of the component are modified until the desired material properties can be achieved. Therefore, a homogeneous temperature distribution over the entire plate surface is required. The precision and consistency of this temperature can be measured by the PRESS-CHECK test system. A high resolution thermal imaging camera can accurately capture the temperature of the heated plates at 950 °C before the pressing operation begins and can also detect the contours of the metal sheets so that a faulty positioning can be prevented. A second camera checks if the cooling process is within the defined quality limits immediately after pressing.

Modern, high-resolution thermal imaging cameras of different spectral ranges guarantee a reliable long-term measurement of temperature distribution. The camera series VarioCAM® High Definition or ImageIR® by InfraTec, with a geometric resolution of up to (2,048 x 1,536) IR pixels, excellent thermal resolution of up to 0.015 K and very high frame rates of up to 13,000 Hz are used.

All components that are classified as faulty by the evaluation are reported and automatic sorted out robotically. This results in a significant reduction of rejection rates, which leads to a significant cost reduction and increase of productivity.

For more information about the camera systems by InfraTec and about PRESS-CHECK, visit www.InfraTec.eu or the InfraTec GmbH booth at the Control 2015 (Hall 1, Booth 1830).