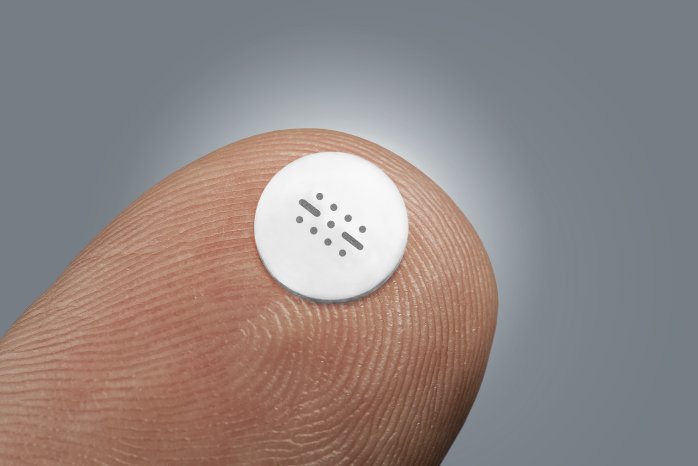

“Medical implants that can be manufactured using the CerMet technology are smaller, more powerful and can integrate more functions – which is a huge advantage for our customers,” says Jens Trötzschel, Vice President Advanced Technologies at Heraeus Medical Components. This is possible thanks to small-scaled conductive paths with a diameter of only 0.15 millimeters – as fine as a piece of paper. More than three million medical devices are already implanted each year to help manage such chronic conditions as cardiac arrhythmia, Parkinson’s, hearing loss or blindness. The new technology opens up new markets for manufacturers of implants and for Heraeus as a supplier, as smarter and more multifunctional devices will help reduce healthcare costs.

CerMet opens up new opportunities for those with visual impairments

CerMet received the Heraeus Innovation Award 2015 for the best product innovation. The strong, high-density and extremely robust CerMet material is a combination of tiny platinum and aluminum oxide particles. Ceramic and metal normally do not bond chemically. This presented the Heraeus team with major challenges during the development of the composite material. The high level of material and system expertise at Heraeus was the key to success.

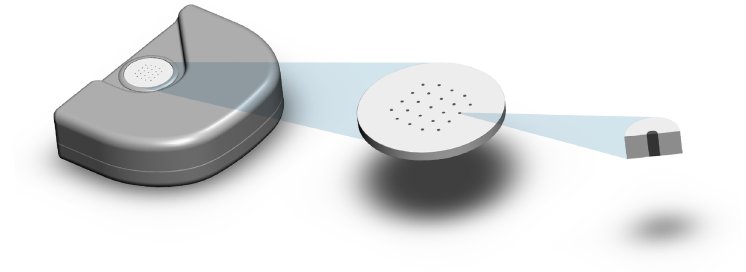

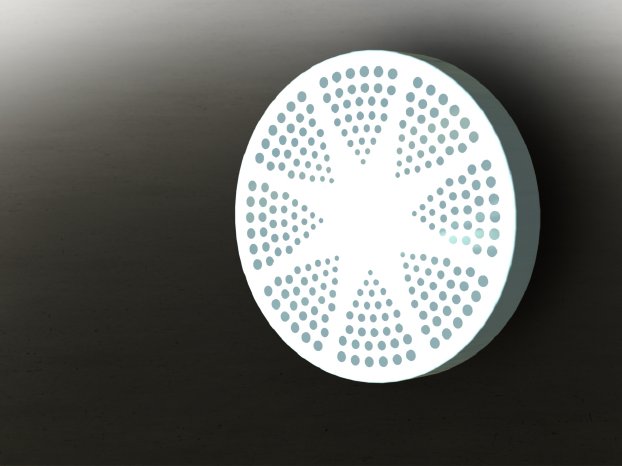

Previously, individual wires had to be inserted in the ceramic manually and then soldered in a high-temperature process that was labor-intensive and time-consuming. However, when many electrical channels are needed, this process quickly reaches its limit and becomes a hurdle in the development of miniaturized devices and new treatments. “With CerMet, it is possible to have 800 electrical channels per square centimeter, which is a major increase over the number that can be added to current implants,” explains Ulrich Hausch, project manager at Heraeus Medical Components. As a result, in the future it might be possible, for example, to implant sensors for those with damaged eyesight exactly where they are needed, which will allow for much more efficient treatment. In the case of ocular prostheses (retina implants), more connector channels for conveying impulses from the implant to the optic nerve could lead to better resolution in the retina. Currently, there are typically 64 channels, which allow patients to make out objects dimly. With CerMet technology, more than 1,000 channels can be placed on the same amount of space, increasing resolution dramatically.

And Ulrich Hausch highlights another advantage: “CerMet offers developers and manufacturers of implants greater flexibility in designing new components because the material system enables the production of more complex three-dimensional structures.” In the area of feedthroughs, it will now be possible to manufacture angled or branched circuit paths, allowing for more design flexibility than ever before. Active medical implants and devices are often still quite large, for example, brain readers that will control prostheses by capturing brain activity. Quadriplegic patients and amputees, in particular, will benefit greatly from these devices. In order to develop devices for everyday use, the brain readers and their feedthroughs will have to become smaller and the interface between the implant and the body must offer a higher level of integration. In future this will be possible with CerMet technology from Heraeus.