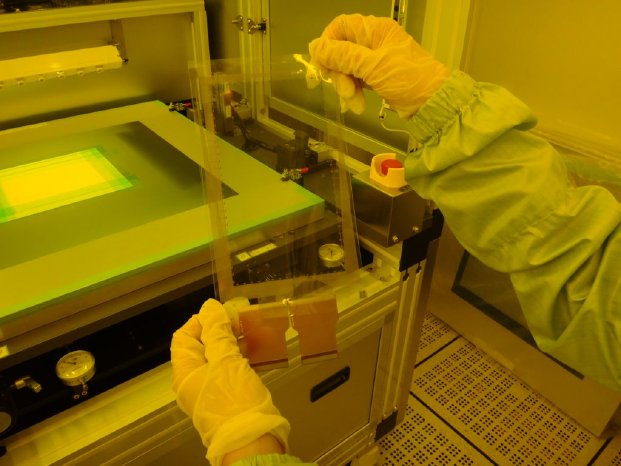

"Our prototype is a fully functional, flexible touch panel that can be produced on an industrial scale. In comprehensive testing, the multi-touchscreen withstood 10,000 bending cycles at a 5 and a 3 millimeter bending radius without any issues," states Dr. Armin Sautter, director of Technical Service Displays at Heraeus New Businesses. Heraeus developed the improvement for mass production of Clevios™-coated films in a collaborative research project with the Industrial Technology Research Institute (ITRI, Taiwan). With this conductive coating, manufacturers can produce touchscreens with improved functionality on an industrial scale - for flexible, curved, three-dimensional touchscreens as well as wearable functional apparel, for example. The 7-inch touch panels can also carry out multi-touch functions with five contact points.

Consumer electronics are driving development

The LOPEC trade fair shows the lightning-fast development in printing processes and materials for the electronics industry and highlights the potential of printed electronics, which are already found in countless everyday items like displays or printed antennas. "The main driver of consumer electronics is ongoing customer demand for improved devices with higher performance," says Dr. Armin Sautter. "From a customer perspective, foldable and rollable displays are extremely important, because customers want larger and larger screens but, at the same time, they want a compact, transportable device. That's actually a contradiction, Press release but one that can be solved in the future with flexible, foldable displays that can be folded and rolled like a newspaper."

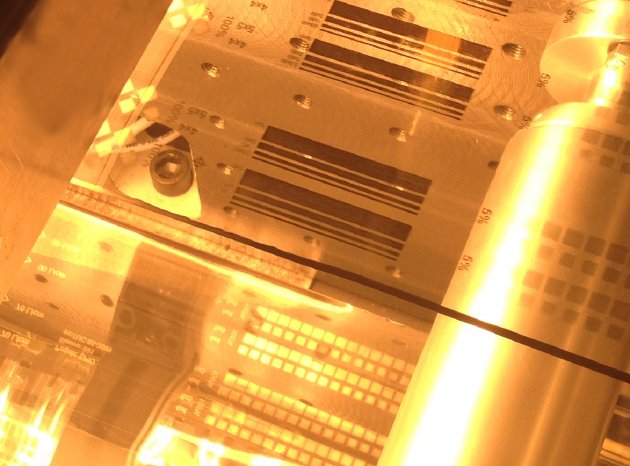

Printed electronics dry 2000 times faster

Heraeus offers a large portfolio of materials and technologies for printed electronics. These include conductive polymers and printing pastes as well as process technologies such as specialty light sources. With printed electronics for displays produced by the meter, in addition to using suitable materials, fast drying surfaces are important, along with good conductivity of the applied silver pastes. An infrared module newly developed by Heraeus achieves this in a fraction of a second (0.32 s.), making it almost 2000 times faster than traditional drying processes with conventional heating plates or hot air. Metallic nanoparticles for printed electronics are frequently applied to flexible, temperature-sensitive polymer materials in an inkjet printing process, then dried and sintered. However, using a roll-to-roll process is necessary for mass production. The optimal process should dry and sinter quickly and efficiently while not damaging the often temperature-sensitive polymer substrates. Heraeus developed a custom infrared module for this purpose that requires 0.32 seconds for drying and sintering. By contrast, this process takes around 10 minutes with a heating plate. Thanks to the custom infrared system the printed electronics on the film roll can be dried and sintered lightning-fast in a single step.