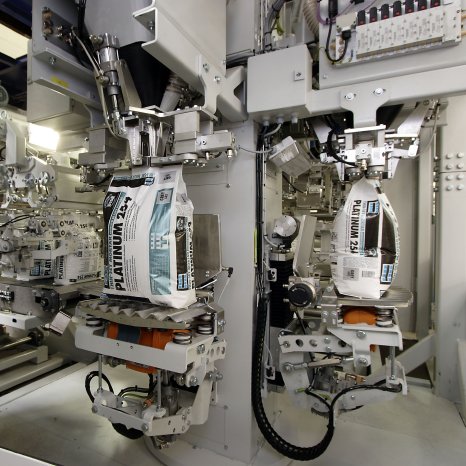

Building chemicals manufacturer ARDEX in Witten Germany, for years a customer of Haver & Boecker, has recognised the advantages of this new machine technology and is the first German building chemical products manufacturer to use the HAVER-BENJAMIN to pack products into polyethylene bags and bring them onto the market. "THE BENJAMIN packing system, based on the HAVER-ADAMS-PROCESS (HAP) machine technology, is the latest milestone in filling technology for bags", says Dr. Reinhold Festge, Managing Director and Partner at Haver & Boecker. In addition the newly developed packing system consisting of polyethylene side-gusset tubular film, this FFS system offers the following advantages:

- compact and dense packing

- high level protection against moisture and oxidation, which makes it possible to store filled bags outside exposed to the weather

- greatly increased storage time capability

- cleanliness during the bag filling process and throughout the entire logistical chain

- an improved optical appearance from high quality bag printing methods with a glossy effect, which increases consumer acceptance and sales

- a compact, stable and perfect stacking of filled bags

- a highly durable packaging…

"…meaning bag breakage is practically eliminated, which is also an advantage with respect to environmental protection," adds Dr. Jochen Billecke, Engineering Director of ARDEX. It's just another plus from this innovative packing system that cannot be underestimated. After a trial phase of several weeks ARDEX became firmly convinced of this new machine technology and the advantages that come with the resulting finished, packed products.