Reinhard Surmann, Key Account and Area Sales Manager HAVER Chemicals, will be explaining why operators of modular facilities respond flexibly to the most diverse requirements during the entire production process and can realize necessary changes in the production more quickly. It is of fundamental importance to minimize interfaces and thus avoid frictional losses. How this can be put into practice will be reviewed in the presentation.

The presentation describes three levels:

1. The first level is the modularity of individual components. For example in a packing facility single machine components are modularly designed, interlocked, and at times can be added later.

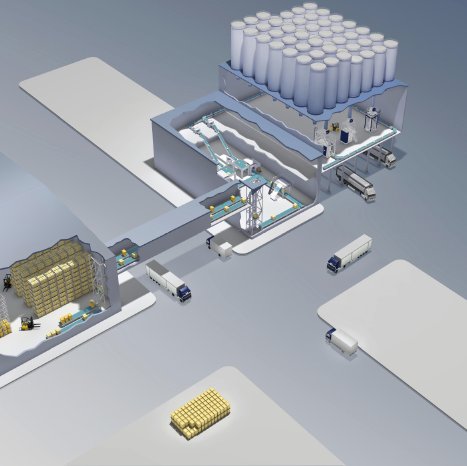

2. In the next level it is explained how technologies of an entire packing line can be combined with each other in a modular fashion. Hence the entire process chain of processing, storage, mixing, packing, filling, palletizing and loading can be set up individually - depending on the customer's requirement. All process steps can be perfectly matched up and controlled.

3. Finally it is examined how cooperation can be done with different partners with the aim of supplementing or varying the named process chain.

These three levels are illustrated by using the example of a production location of one of the world's largest petrochemical companies. Here various packing machines, hood film-stretchers and truck loading systems are combined with each other. By looking at a practical application of the modularization concept, the advantages will be explained.

Automation technology takes on a special function with packing facilities which have a modular set-up. A process control system for operating, monitoring and controlling the production process assures that all steps are interlocked. A system for organization and automation of the shipping department for loose-bulk and packed materials supplements the spectrum. The presentation looks at the possibilities and advantages of automation technology at all three levels.

www.haverboecker.com