The product spectrum already consists of a number of standard motors. Now the POWER LINE program has been extended and the ATEX certified motors have been added: the sizes from 1.6 to 6 kW are accredited in accordance with directive 2014/34/EU from 26th February 2014 for use according to EX II 2 GD c IIC T3 (200°C).

In accordance with 2014/34/EU, machines in category 2 are designated for use in areas where a potentially explosive atmosphere consisting of gases, steam, smoke or a dust-air mixture is occasionally likely to arise. The machine-based explosion prevention measures in this category guarantee the required extent of safety even if there are frequent device errors or error statuses.

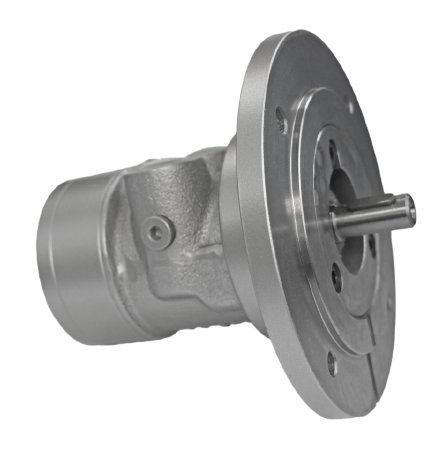

Air motors are already in themselves ideally designed for this type of application. The functional principle of an air vane motor is simple: The compressed air generated by the compressor begins motor rotation. The rotor begins to revolve in the eccentric cylinder. In its slots there are vanes which are pushed against the outside of the cylinder wall by centrifugal force. Working chambers are generated for the expanding compressed air. The expansion means that the compromised air changes the pressure energy into kinetic energy – resulting in the rotational movement. The expanded air cools down and it becomes really cold around the motor. Therefore, the risk of gasses becoming ignited by high temperatures is significantly reduced by using an air motor.

All new ATEX conform motors can be recognised by their type key: the conformity of the 68X-001F09/IEC71 is clearly indicated by the “X” in the type description.

As well as the ATEX certification, DEPRAG engineers have also further optimised the existing POWER LINE motors, this means: the same motor size is now even more efficient! The previous power range of all motors has been increased from 2.6 kW to 3.2 kW or from 3.6 kW to 5.0 kW and 6.0 kW.

Due to the high speeds of vane motors, gears are frequently required for speed regulation. With DEPRAG, machine builders are saved from the extensive design work and interface adjustment between gear and motor. The drives are equipped with a standardised IEC-flange connection such as that used for electric motors and standard gears. The IEC-flange enables the connection of varying ATEX conform standard gears. This may include planetary gears, spur gears, worm gears, bevel gears or other gear types.

In addition, all drives in the catalogue are also reversible i.e. the motors work in both rotational directions. The air motors can be controlled using an external directional control valve. Alternatively, there are also air motors in the program which can be manually controlled with a lever.

POWER LINE vane motors with power of 1.6 to 5 kW are also available with integrated brake. The holding brake is controlled via a separate control line. If the pressure in the brake line falls, then the holding brake is automatically activated. If the operating pressure in the control air connection for the motor brake is higher than 5 bar, then the motor spindle will turn freely.

It is important for the DEPRAG engineers that the motor is deployed in an energy-efficient way. The air motors are characterised by their speed adaptation feature, which adjusts automatically according to load variations. When load is removed the air motors run at idle speed. If low load is conflicted, when there is low torque on the motor spindle, the working speed approaches the idle speed. The working speed is reduced as soon as the torque increases. At 50 percent of the idle speed the air motor achieves its maximum power. "This is also the optimal working range of the air motor. In the range of 40-50% of the idle speed the air motor works particularly energy-efficiently. This is a criterion which we consider carefully during motor design", explains the DEPRAG Product Manager for air motors Dagmar Dübbelde.

It is also important that the correct dimensions of the air motor are ascertained during the planning stage. There are theoretical characteristic curves available for all DEPRAG air motors. The specialists at DEPRAG support their clients in the planning of the right motor for the customer’s individual application case.

Product Manager Dagmar Dübbelde is pleased with the new developments in the product group: “DEPRAG SCHULZ GMBH u. CO. is undergoing a long-term progression in innovation for the further development and adaptation of the product spectrum in accordance with the requirements and individual applications of our clients. This latest development means that we have reached this target”.

DEPRAG SCHULZ GMBH u. CO. based in Amberg, Germany is represented in over 50 countries with approx. 600 employees worldwide. DEPRAG is a market leader in the manufacture of air motors. In their standard programme, the owner-operated family business offers a wide range of variations from which individual drive solutions can be developed and manufactured for any application according to a modular principle at an attractive price-performance ratio.