When the timing belts are changed, the tension pulley, the guide pulley and the water pump should be replaced, too. Renault recommends a belt change every 100,000 km for all models up to 1999, and every 120,000 km for all later models, or for low mileages.

In order to do this, mechanics require a crankshaft locking pin, Renault tool code MOT1489, and a camshaft alignment ruler, Renault tool code MOT1496. The working time is for the Clio about 2.7, for the Mégane 3.6, for the Mégane Scénic 3.9 and for the Laguna 2.5 hours.

Preparatory work:

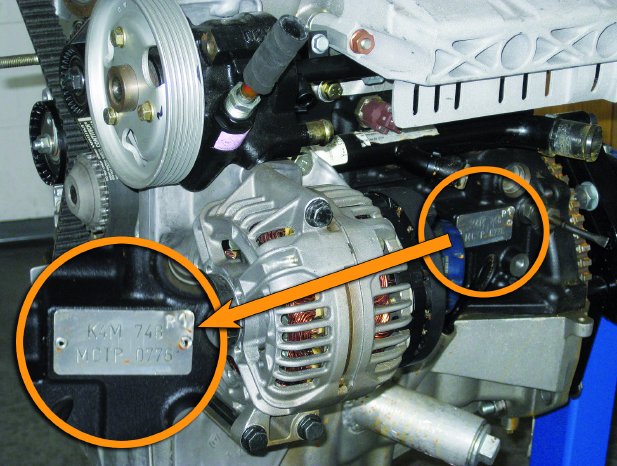

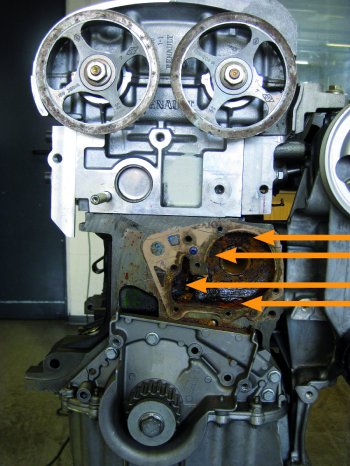

Identify the vehicle using the engine code on the engine block (Fig. 1). Disconnect the vehicle's battery.

Removal:

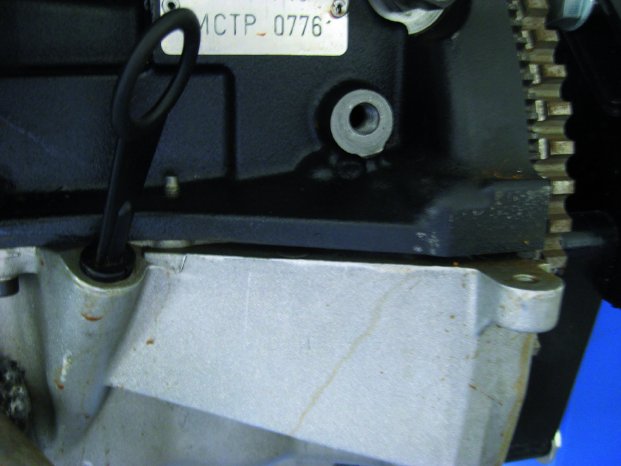

Drain the cooling water and support the engine. Then remove the right engine mount first and then the ancillary units with drive belts (Vribbed belts). Remove the plugs from the rear end of the camshaft and the plugs from the cylinder block (Fig. 2).

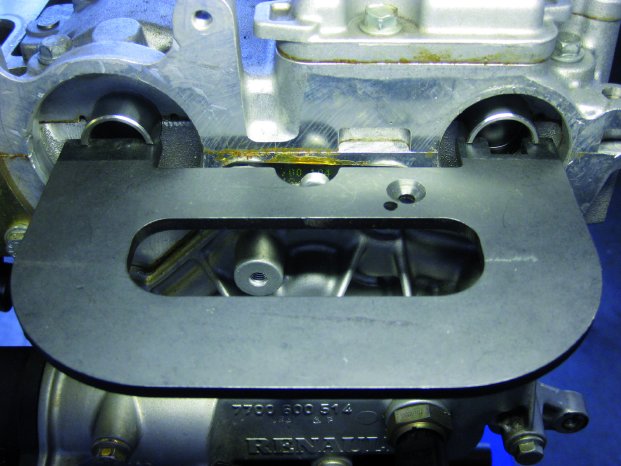

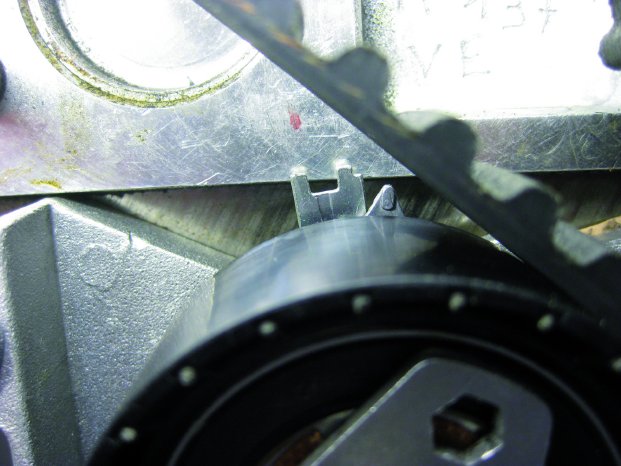

Turn the crankshaft to the right to the setting position. The grooves in the camshafts must be aligned (Fig. 3).

Note: The grooves are located below the top edge of the cylinder head.

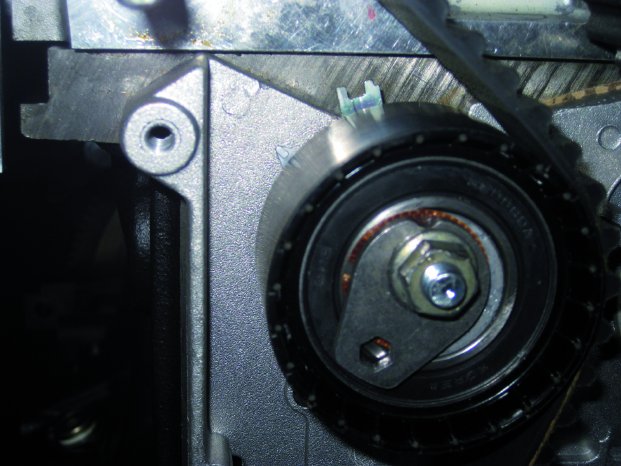

Then insert the locking pin into the cylinder block (tool code MOT1489, Fig. 4). The crank web must be up against the locking pin.

Then apply the alignment ruler at the rear end of the camshafts (tool code MOT1496, Fig. 5).

Block the flywheel using a large screwdriver or a suitable tool and loosen the screw of the crankshaft belt pulley.

Note: The flywheel must be securely blocked so that the locking pin does not break or become bent, or that the camshaft ruler or the camshaft itself is not damaged when loosening the crankshaft screw.

Now remove the screw from the crankshaft belt pulley and take the pulley off. Then remove the top and bottom timing belt cover.

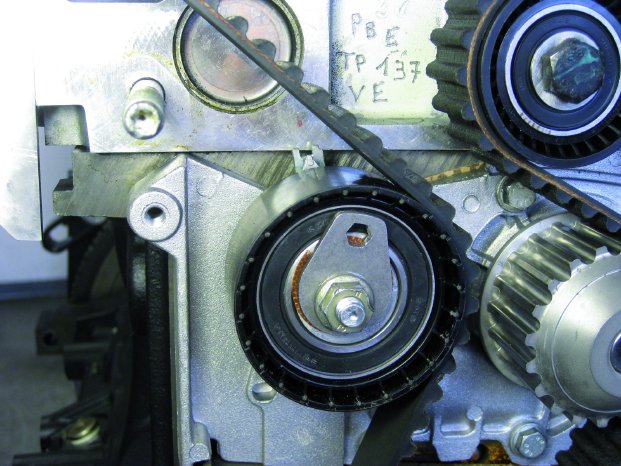

Loosen the nut of the tension pulley and let the tension pulley come away from the belt (Fig. 6).

Now, you can remove the tension pulley nut, the tension pulley, the guide pulley, the timing belt and the water pump.

Note: The crankshaft gear must not slip off the crankshaft.

Installation:

Check whether the locking pin is inserted. The crankshaft must be up against the locking pin. The grooves in the camshafts must be aligned. Also check whether the alignment ruler is correctly applied.

Then install the new water pump.

Note: Carefully clean the sealing surface between engine block and water pump and remove any remaining seal (Fig. 7).

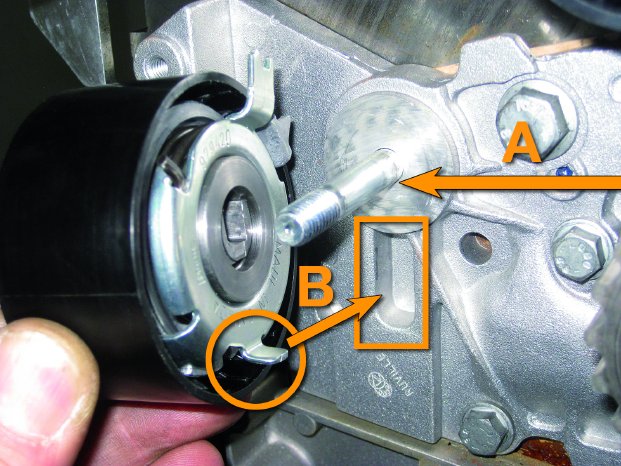

Note: Pay attention to the tightness of the bolt that holds the tension pulley in the water pump housing (Fig. 8 A).

Install the new guide pulley and tighten to 45 Nm. Then install the new tension pulley and tighten the nut to 7 Nm for the time being.

Note: Make sure that the retainer clip to the rear side of the tension pulley correctly grips into the groove in the water pump housing (Fig. 8 B).

Remove the crankshaft gear and gear. Ungrease the end of the crankshaft. Reinstall the crankshaft gear.

Fit the timing belt going around towards the left starting from the crankshaft gear. Make sure that the timing belt is tight on the load side.

Ungrease the crankshaft belt pulley and then install it. Measure the length of the screw of the crankshaft belt pulley. The maximum length must not exceed 49.1 mm. If the screw is longer, then you must use a new one. Screw in the crankshaft belt pulley screw. Do not oil the new screw. Tighten the screw for the time being. Leave a gap of 2-3 mm between the contact surface of the screw and the crankshaft belt pulley.

Loosen the nut of the tension pulley. Turn tension pulley to the right until the movable pointer is at the right stop. Use a 6 mm hex key.

Note: The movable point must be 7-8 mm behind the fixed pointer (Fig. 9).

Tighten the tension pulley nut for the time being, tightening torque: 7 Nm.

Block the flywheel with a large screwdriver and tighten the screw of the crankshaft belt pulley for the time being, tightening torque: 20 Nm.

Remove the locking pin and the alignment ruler.

Block the flywheel with a large screwdriver and tighten the screw of the crankshaft belt pulley by a further 120-150 degrees.

Turn the crankshaft two rotations to the right into the setting position. This is an extremely important step. If this is not done, the belt drive will start making noise in a short time due to insufficient tension.

Insert the locking pin into the cylinder block. The crank web must be against the locking pin.

Check whether you can easily apply the camshaft alignment ruler.

Lock the tension pulley using a 6 mm hex key. Loosen the nut of the tension pulley.

Turn the tension pulley to the left until the pointer is aligned with the notch (Fig. 10). Tighten the tension pulley nut, tightening torque: 27 Nm. Remove the locking pin.

Turn the engine drive two more times, check the setting and adjust if necessary.

Insert the plug by turning and insert new plugs at the end of the camshaft.

Install the components in reverse order of removal. Fill up the cooling water and vent the cooling system.

Record the replacement of the original ContiTech timing belt on the supplied sticker and affix it in the engine compartment (Fig. 11).