- Alternative suspension means offers advantages in comparison to steel ropes

- Long lifespan reduces maintenance costs

- Available in 25 mm and 50 mm wide versions

- Profiled back side allows narrower construction width

With the CONTI® POLYROPE, ContiTech further develops the successful flat belt technology, which was introduced in the elevator industry in the late 1990s. The CONTI® POLYROPE is certified according to the Lift Directive 95/16/EC, available in two different widths, with and without profiled back side and offers numerous advantages compared to conventional steel ropes.

Over 100 years, steel ropes were indispensable as suspension means for elevators. Around the turn of the millennium, first alternatives came up with robust polyurethane belts, which were much lighter than steel ropes, allowing more efficient drives and easier maintenance. Now, ContiTech pursues this development: "The composite rope CONTI® POLYROPE is a patented solution of ContiTech," says Hubert Göser, head of research and development at the ContiTech site in Dannenberg, Germany. "It is available on the free market for elevator manufacturers all over the world."

Advantages in comparison to steel ropes

The CONTI® POLYROPE features 2 mm thick steel ropes consisting of 49 individual strands, which are embedded in a polyurethane coating. They give the suspension means its high tensile and breaking strength. The coating is durable, resistant to hydrolysis and has very good traction properties: even at maximum load, a reliable power transmission is given. The CONTI® POLYROPE is available in 25 mm and 50 mm wide versions and with a flat as well as with a profiled back side.

As a result, the product offers an extremely long life span. The CONTI® POLYROPE holds up to three times longer than comparable steel ropes and is 20 % lighter, it also does not need to be lubricated. This helps to reduce downtime and maintenance costs.

More space in the shaft

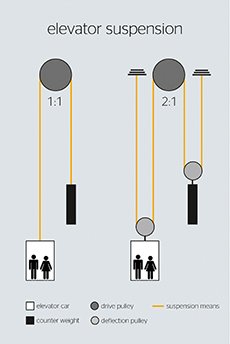

While the inner side of the CONTI® POLYROPE is fluted and lead exactly on accordingly profiled drive pulleys, the prototype has a flat back side. Since the flat side of the CONTI® POLYROPE runs over deflection pulleys in a 2:1 suspension, these are slightly curved outwards, so that the suspension means can centre up. Due to the convex shape, drive and guide pulleys need to be wider than with steel cables.

For this reason, ContiTech has developed more variants of the CONTI® POLYROPE, with back sides featuring a profile. "Deflection pulleys can be provided with a corresponding profile, which enables a smaller and narrower construction width. Thus they take even less space in the elevator shaft," says Göser. "The obtained space can be used for other components."

Certified by renowned testing institute

The approval of the CONTI® POLYROPE as suspension means for elevators was granted by the Dutch testing agency Liftinstituut after successful examination. "The Liftinstituut is internationally renowned in the elevator industry," says Göser. "Thus, a certification by the Liftinstituut opens doors for marketing in the whole world." The CONTI® POLYROPE is not yet fitted as standard - but the developments of elevator manufacturers are in full swing.