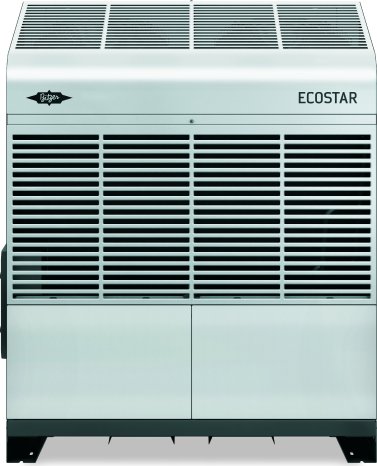

With the new ECOSTAR LHV7E, BITZER now provides an air cooled condensing unit that conforms with all EU Directives and offers users unrivalled energy efficiency, which is essential in an environment of rising energy prices. The low-maintenance, easy-to-use device also boasts reliable, low noise operation and simple installation.

Modern fans and compressors

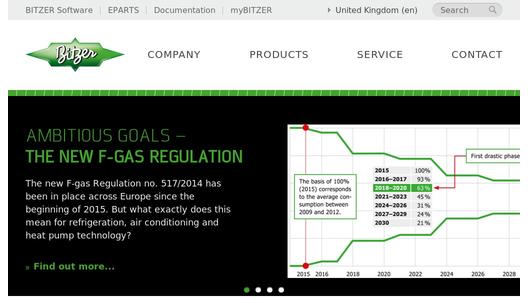

BITZER has optimised the condensing unit with a particular focus on the F-gas Regulation and the 2016 EU Ecodesign Directive. The integrated EC fan of the ECOSTAR LHV7E reduces the noise level and energy consumption significantly. The optimised control allows the user to adjust the speed of the fans and the ECOLINE VARISPEED compressor at any time for more energy-efficient operation. The optimised mini-channel condenser also improves eco-efficiency: compared to the older ECOSTAR models, the LHV7E requires a lower refrigerant charge while offering higher heat exchange.

The LHV7E is also extremely quiet: its low noise EC fans feature sound-optimised airflow and the compressor is located inside a sound-damping housing. When the cooling load is normal, the system can be operated in ECO or low-sound mode. Thanks to its energy-optimised, quiet operation, the LHV7E is the right condensing unit today for the applications and challenges of tomorrow.

Remote control and simple maintenance

As expected, the new ECOSTAR condensing unit has proven itself to be reliable in extensive field tests. One ECOSTAR LHV7E has also undergone many other tests with a VARISPEED compressor, including the new refrigerant injection (RI) and R407F, and convinced across the board in the low temperature application, thanks to stable operation with acceptable discharge gas temperatures even in high ambient temperatures. The optimised Lodam controller with newly integrated Bluetooth technology has proven to be a helpful feature, ensuring technician-friendly operation of the ECOSTAR and working seamlessly at a distance of 30 meters away. The ECOSTAR LHV7E is easier to use than its predecessors: the condensing unit can be controlled and serviced remotely via an Ethernet connection for networks or the Internet, Modbus RTU and Bluetooth access using BITZER’s BEST software. There’s also a display for operation, which comes integrated into the controller housing and offers optimised menu access. The BEST software or an optional retrofit display provides users with full access to all the menu options.

Another new feature is that up to four ECOSTAR condensing units can be linked together via the Modbus. Together the condensing units form an ECOSTAR control network and, in optimised interaction, control the temperature of a cold store without having to be connected in the refrigerant circuit.

The control electronics of the LHV7E are fully wired in the factory and come ready for operation, facilitating fast installation of the condensing unit on-site. To simplify maintenance of the device, BITZER has optimised access to the important components: each of the two casing parts can be opened with a captive screw. The terminal box, the filter drier, the sight glasses and the oil separator can easily be accessed in no time from the outside.

Suitable for lots of applications

The ECOSTAR LHV7E is available in six variants, four of which offer a capacity of up to 42 kW (0/32/20@R134a). Depending on the model, it’s compatible with the refrigerants R134a, R404A, R507A, R407A, R407C and R407F, which means BITZER enables a whole host of applications for this condensing unit. With its compact design, the condensing unit also fits into smaller engine rooms, while the robust housing also makes it suitable for outdoor use. The integrated winter start feature allows the compressor to be started even in winter when the ambient temperature falls below the saturated suction temperature.

The BITZER LHV7E condensing unit comes standard with an integrated frequency inverter and filter drier. Optional features include an oil separator with check valve, oil monitoring and an additional check valve for installation in low ambient temperatures.