The future of mobility – this is the motto of this year’s InnoTrans trade fair. The future of transport also keeps the world’s largest independent manufacturer of refrigeration compressors, BITZER, moving each day. At InnoTrans 2016, the traditional company will be showcasing energy-efficient refrigeration compressors for mobile applications, thereby making great strides towards the refrigeration and air-conditioning technology of tomorrow.

SPEEDLITE scroll compressors for railway carriages

With the SPEEDLITE series, BITZER presents a compressor solution ideally suited for rail applications. In the development of semi-hermetic scroll compressors, special emphasis was placed on combining compact design with low weight and high performance. Visitors will have the opportunity to see this for themselves at the trade fair, as Oliver Rathfelder, Director Sales Transport at BITZER, explains: ‘At this year’s InnoTrans, we will present a functional SPEEDLITE model in a running system. Visitors to the fair will get to witness the benefits of our new compressors up close and personal.’

With SPEEDLITE ELV21 and ELV51, there are two production series on hand. Both series have a large range of control where the compressor capacity can be easily adapted to all operating conditions. This ensures optimal full and partial load efficiency. Thanks to the already integrated frequency inverter, the compressors are easy to install.

Optimised capacity control through CRII

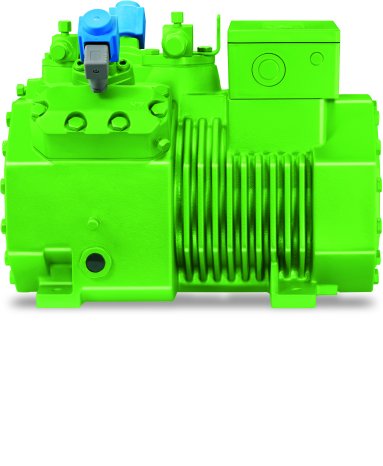

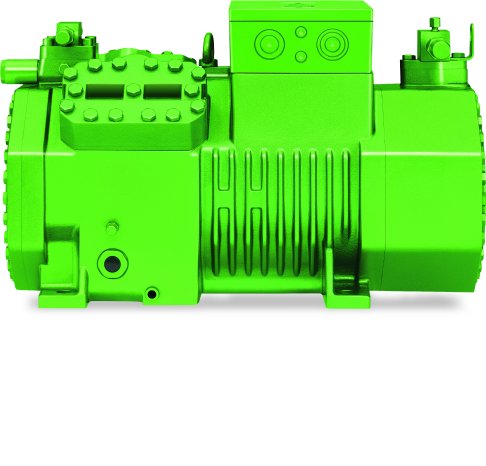

Also available at the exhibition stand: Semi-hermetic reciprocating compressors from the ECOLINE series with optimised CRII capacity control and the H series, an expansion of the proven ECOLINE compressor series. The drive gear was adapted here to guarantee certain emergency running characteristics under difficult operating conditions and meet the special requirements of mobile use. CRII takes the place of the previous BITZER CR system and is available as an optional accessory for the new generation of ECOLINE compressors. Its unbeatable benefit: the backwards-compatible system enables practically infinite capacity control. This enables system efficiency to be increased by up to 15 per cent, pressure fluctuations to be reduced and evaporation temperature to be raised. In the case of a change of load, the system only needs a short response time whereby the compressor capacity can be adapted to the actual cooling demand.

CRII is based on the principle of blocked suction and is particularly relevant for systems which require convenient capacity control. Using an adapted control algorithm, the compressor is almost infinitely variable. With the CRII, BITZER has achieved an exceptionally wide range of control between ten and 100 per cent for four- and six-cylinder compressors. The increased switching frequency, however, ensures smaller fluctuations in temperature and pressure and, in combination with the expanded range of control, optimises system efficiency, protects the environment and reduces operating costs.

Climate-friendly on the go with CO2 compressors

Furthermore, BITZER meets the high demand for climate-neutral solutions for cooling and air conditioning applications with its CO2 compressors. With its comprehensive product range, the compressor specialist offers the right product for every customer. BITZER is presenting its CKH3 compressor at the trade fair. Quiet and low in vibration, it is optimised for cooling and air conditioning applications and is also ideally suited for use with frequency inverters. The infinite speed control ensures optimal part-load efficiency. BITZER provides training regarding proper handling of CO2 compressors to industry experts at its in-house SCHAUFLER Academy.