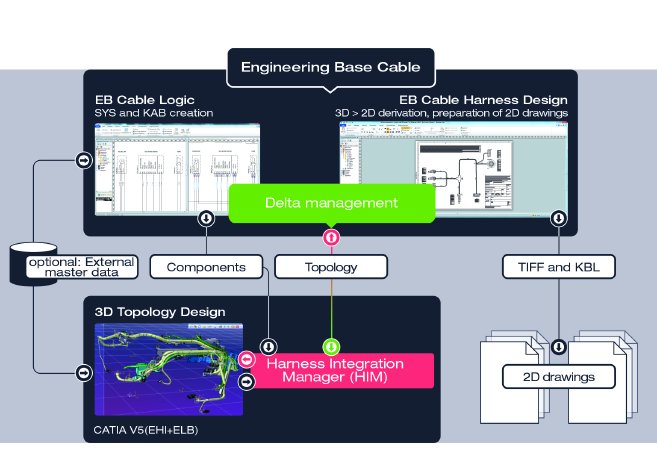

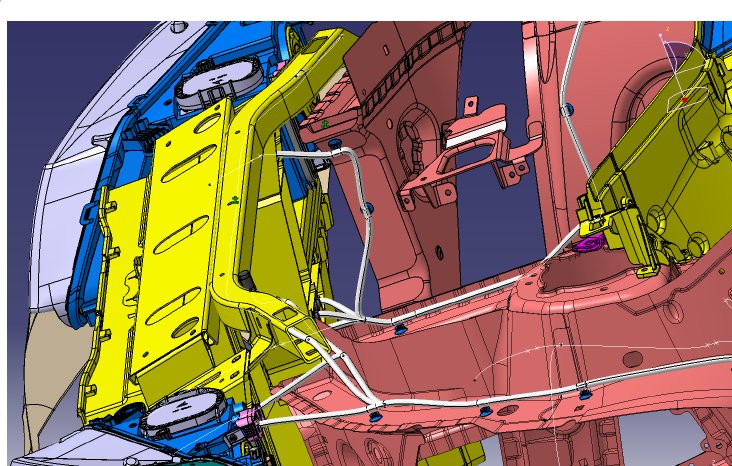

For planning this variety of configuration options, which amount to hundreds of thousands, Aucotec offers, with Engineering Base (EB), a system that maps the full complexity of harness design with all of its relationship knowledge. This is made possible by a central data model that covers the complete workflow, from the wiring-independent 150% system design via the 150% cable diagram and data output in the KBL-XML standard down to laying and layout in 2-D and 3-D as well as finally the deployment of the actual individual KSK data relevant for manufacturing. Derived documents such as form board layout or parts lists are generated automatically – and all that without system breaks, multiple entries or manual supplements. Sources of error do not occur any more, and the data quality increases in spite of distinct time economy.

Synchronous project processing

Hundreds of modules, plugs and splices, several kilometers of cable, more than 1,000 individual lines: all disciplines involved access this centrally stored data. EB immediately recognizes and marks changes in each of the planning stages, they can be retrieved by everybody involved anytime. This enables synchronous project editing by several users. EB also supports asynchronous, site-independent operation in different installations, e.g. at suppliers' premises, via an efficient delta management.

Efficient manufacturing

In addition to supplying data relevant for manufacturing, EB supports harness design manufacturers also via an automated analysis of the manufacturer-specific modularization and the resulting structuring of the production. This kind of work could formerly cost several man weeks. EB offers the relevant information at the push of a button.